Electrical conductivity is one of the most frequently measured parameters in water quality analysis. It indicates the ability of water to conduct an electric current, which correlates directly with the concentration of dissolved ions such as salts, minerals, and inorganic compounds. For professionals working in environmental monitoring, drinking water treatment, or industrial process control, understanding the correct conductivity unit is essential for accurate data interpretation and reporting.

This article explains the standard conductivity unit used in water monitoring and introduces a reliable instrumentation solution—the SPECSENS SPS-EC Conductivity Water Quality Sensor—designed to deliver precise, stable measurements across a wide range of applications.

Understanding Conductivity Units in Water Monitoring

The International System of Units (SI) defines electrical conductivity in siemens per meter (S/m). However, because most water samples have conductivities that are far lower than 1 S/m, scaled units are used in practice to simplify reporting and interpretation.

The Standard Unit: µS/cm (Microsiemens per Centimeter)

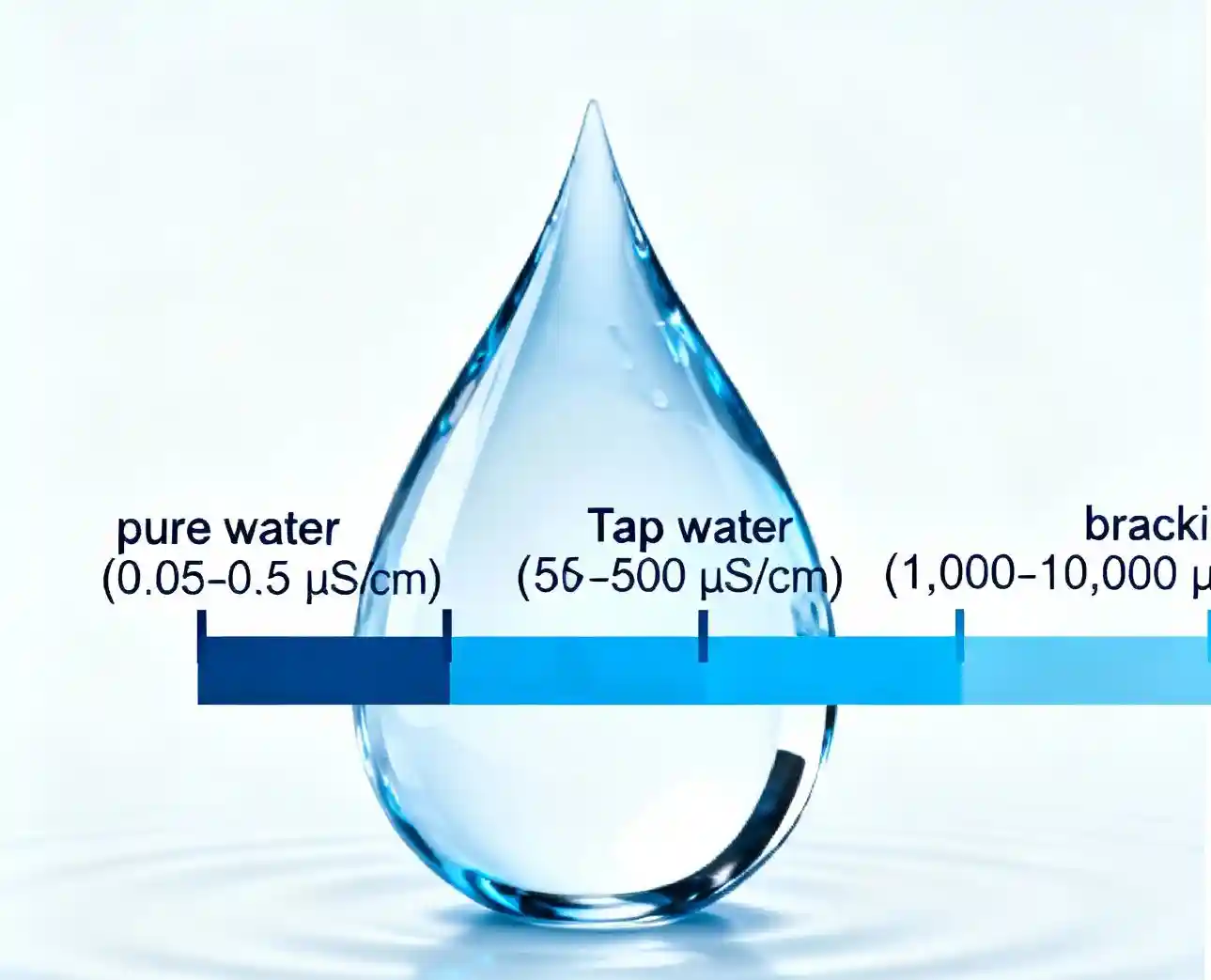

In water quality monitoring, microsiemens per centimeter (µS/cm) is the most widely adopted unit. Its popularity stems from several factors:

- Convenient Numerical Range

Freshwater, drinking water, and treated wastewater typically exhibit conductivities between 10 µS/cm and 2,000 µS/cm. Using µS/cm avoids scientific notation and simplifies data logging. - Global Recognition

Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the World Health Organization (WHO) often refer to µS/cm in water quality guidelines. It has also replaced the legacy unit micromhos per centimeter (µmho/cm), with which it is numerically equivalent. - Direct Relation to Derived Parameters

Conductivity in µS/cm is commonly used to estimate Total Dissolved Solids (TDS) in milligrams per liter (mg/L) or parts per million (ppm). The conversion is typically performed using a factor between 0.5 and 0.9, depending on ionic composition.

Other Commonly Used Conductivity Units

| Unit | Symbol | Typical Use Case |

|---|---|---|

| Millisiemens per centimeter | mS/cm | Brackish water, seawater, industrial wastewater |

| Millisiemens per meter | mS/m | Some scientific publications and EU regulatory frameworks |

| Total Dissolved Solids | mg/L or ppm | Drinking water reports, aquaculture, hydroponics |

The Role of Temperature Compensation

Conductivity is temperature-sensitive. To ensure comparability across measurements, readings are usually corrected to a standard reference temperature of 25°C. Modern sensors integrate temperature compensation algorithms to automatically adjust output values.

How to Select a Conductivity Sensor for Water Monitoring

Choosing a conductivity sensor involves evaluating several technical and operational factors:

- Measurement Range – Must cover expected conductivity levels in your application.

- Accuracy and Stability – Especially important for compliance monitoring and process control.

- Sensor Design – Electrode configuration and materials affect polarization resistance and long-term drift.

- Output and Integration – Compatibility with existing data loggers, SCADA, or IoT platforms.

- Environmental Rating – IP classification for submerged or harsh environment use.

- Maintenance Requirements – Affects total cost of ownership.

Recommended Solution: SPECSENS SPS-EC Conductivity Water Quality Sensor

For professionals seeking a robust, accurate, and easy-to-integrate conductivity sensor, the SPECSENS SPS-EC series offers a compelling solution.

Key Features

- Wide Measuring Range

0.001–200,000 µS/cm conductivity, with derived TDS (0.01–100,000 mg/L) and salinity (0.01–120,000 mg/L) values. - Four-Electrode Technology

Coaxial graphite electrode design with a reference electrode reduces polarization effects and improves measurement stability. - Integrated Temperature Compensation

Built-in PT1000 temperature sensor provides real-time compensation to 25°C reference. - Industrial Communication Interface

RS485 output with Modbus RTU protocol ensures compatibility with most monitoring and control systems. - Robust Construction

PVC-U housing, IP65/IP68 ratings, suitable for flow-through or submerged installation in pipelines, tanks, and open channels.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Conductivity Range | 0.001–200,000 µS/cm |

| TDS Range | 0.01–100,000 mg/L |

| Salinity Range | 0.01–120,000 mg/L |

| Temperature Range | 0–50°C |

| Accuracy | ±5% (conductivity/TDS/salinity), ±1°C (temperature) |

| Power Supply | 12–24 V DC |

| Communication | RS485, Modbus RTU |

| Installation | Submerged or flow-through |

| Cable Options | Direct cable (6 m) or aviation plug (2 m) |

Typical Applications

- Municipal drinking water treatment and distribution networks

- Surface water and groundwater quality monitoring

- Industrial effluent and process water control

- Aquaculture, hydroponics, and environmental research

Conclusion

Understanding conductivity units—particularly the widely used µS/cm—is fundamental for accurate water quality assessment. When selecting a sensor, it is important to consider measurement range, accuracy, environmental suitability, and integration capabilities.

The SPECSENS SPS-EC Conductivity Water Quality Sensor provides a reliable, industrially hardened solution for continuous monitoring across diverse water matrices. Its four-electrode design, wide measurement span, and standard communication protocol make it suitable for both regulatory compliance and operational process control.

Explore the full specifications of the SPS-EC sensor or request a sample evaluation by visiting the SPECSENS product page or contacting our technical support team.

Frequently Asked Questions (FAQ)

Q1: Why is µS/cm preferred over S/m in water monitoring?

A: µS/cm provides more manageable numbers for typical water samples (e.g., 10–2,000 µS/cm) and is widely recognized in international water quality standards.

Q2: How do I convert conductivity to TDS?

A: TDS (mg/L) ≈ Conductivity (µS/cm) × k, where k is a factor usually between 0.55 and 0.75. The exact factor depends on the ionic composition of the water.

Q3: Does the SPECSENS SPS-EC require frequent calibration?

A: The sensor is designed for stability and low maintenance. Periodic verification against standard solutions is recommended, but calibration intervals can be extended under stable operating conditions.

Q4: Can the sensor be used in seawater?

A: Yes, with a range up to 200,000 µS/cm, the SPS-EC is suitable for seawater monitoring (seawater conductivity ≈ 50,000 µS/cm).

Q5: Is the sensor compatible with IoT platforms?

A: Yes, the RS485/Modbus RTU output can be connected to most industrial gateways or data loggers for integration into IoT-based monitoring systems.