Choosing the right sensor for your Wastewater Treatment Plant (WWTP) depends almost entirely on what you need the data for (compliance vs. process control) and how quickly you need it.

The following guide breaks down the differences between COD, TOC, and BOD, clarifies the critical distinction between simple “probes” and complex “analyzers,” and helps you decide which technology fits your plant’s needs.

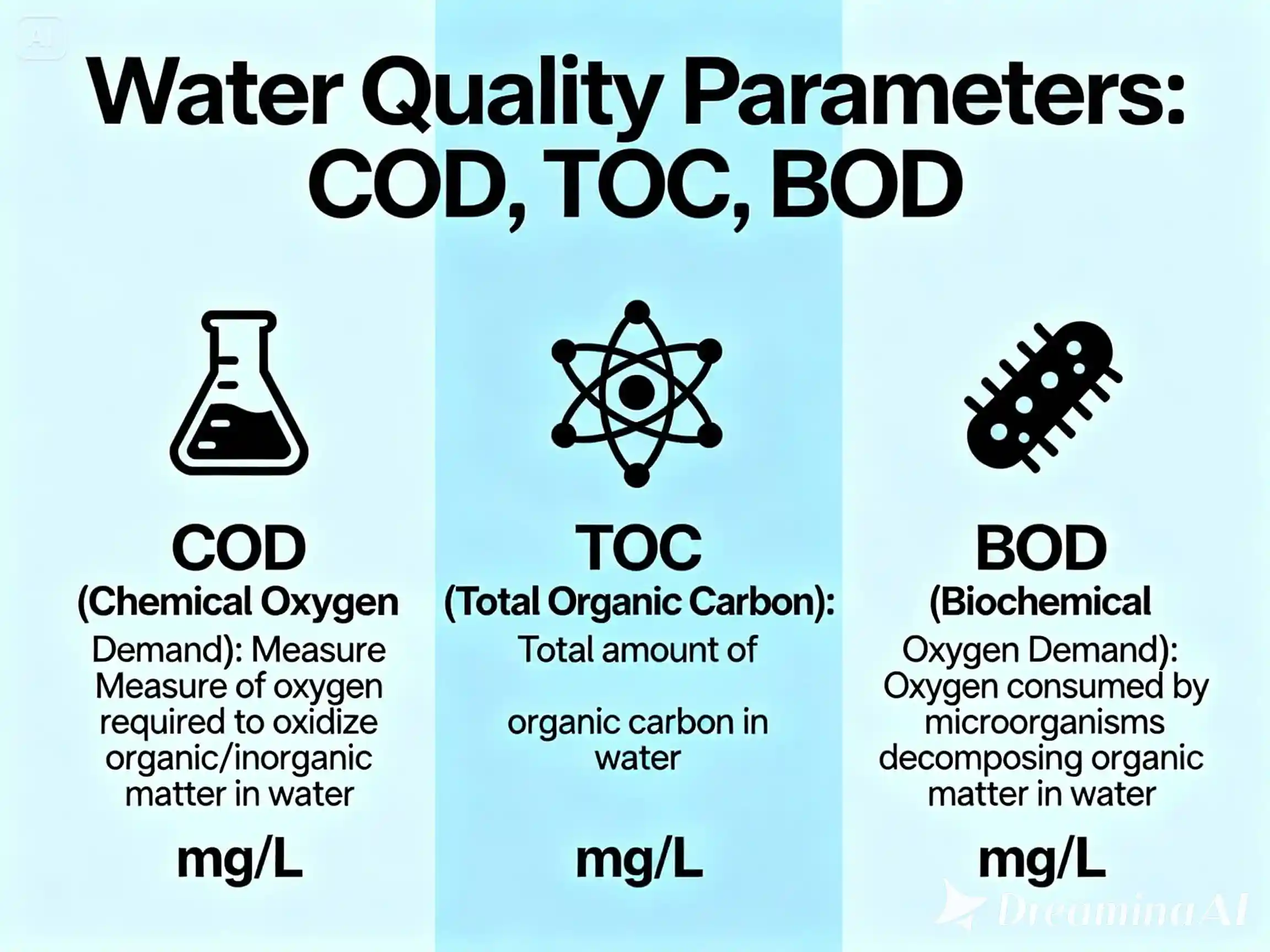

1. The Core Parameters: A Quick Comparison

| Parameter | Full Name | What it Measures | Time to Result | Primary Use |

|---|---|---|---|---|

| BOD | Biochemical Oxygen Demand | Oxygen consumed by bacteria to eat biodegradable organics. | 5 Days | Compliance: Most discharge permits require this. |

| COD | Chemical Oxygen Demand | Oxygen required to chemically oxidize all organic matter. | ~2 Hours (Lab) 1 min (Optical) |

Industrial & Control: Used for toxic waste or rapid process checks. |

| TOC | Total Organic Carbon | The actual amount of carbon in organic compounds. | 5-10 Minutes | Precision: Fast, accurate, and catches non-biodegradable pollutants. |

2. The “Sensor” vs. “Analyzer” Choice

Before choosing a parameter, you must choose the technology type. This is the biggest factor in cost and maintenance.

A. Optical Sensors (Probes)

- What they are: Submersible probes that use UV light (spectral absorption) to estimate COD, BOD, or TOC.

- Pros: Instant readings, zero reagents (no toxic waste), low operating cost, no pumps/tubes.

- Cons: Less accurate than lab methods. Susceptible to interference from turbidity (cloudiness) and color.

- Best For: Process Control. Trending data to automate aeration or detect shock loads.

B. Online Analyzers (Cabinets)

- What they are: Mini-laboratories inside a cabinet that pump a sample out of the water and perform a chemical reaction (wet chemistry or combustion).

- Pros: High accuracy, comparable to lab results. Can handle complex wastewater matrices better than probes.

- Cons: Expensive to buy and maintain. Require reagents (monthly cost) and generate waste. Pumps and tubes can clog.

- Best For: Strict Monitoring. Industrial effluent tracking or replacing lab testing (if regulation allows).

3. How to Choose: A Decision Guide

Scenario A: “I just need to meet my discharge permit.”

- Choice: BOD (Lab Method)

- Why: Most municipal permits explicitly require BOD5. No online sensor can directly measure BOD5; they only provide an estimate. You typically cannot replace the legal requirement for a 5-day lab test with a sensor.

- Strategy: Stick to manual lab sampling for the permit. Use an online sensor (Scenario B) if you want to predict if you will pass.

Scenario B: “I want to automate my aeration blowers to save energy.”

- Choice: Optical COD or TOC Sensor (Probe)

- Why: You need real-time data (seconds, not hours) to adjust air flow as the “food” load changes.

- Recommendation: A UV-Vis Spectral Sensor. It measures the organic load instantly. You can calibrate it to display “COD” or “BOD” values based on a correlation with your lab data. It requires wiping (often automatic) but no chemicals.

Scenario C: “I run an industrial plant with toxic chemicals (Microchips, Pharma, Chemical).”

- Choice: TOC Analyzer

- Why: Toxic chemicals kill the bacteria used in BOD tests, making BOD useless. COD tests use hazardous mercury/dichromate.

- Recommendation: A Combustion TOC Analyzer. It oxidizes everything, giving you a true measure of carbon load in minutes. It is the gold standard for “spill control” in industry because it catches solvents and complex organics that other tests miss.

Scenario D: “I have high chloride levels (e.g., seawater, tannery, pickling).”

- Choice: TOC Analyzer (or special COD kit)

- Why: Chlorides interfere heavily with standard COD tests (causing false highs).

- Recommendation: TOC is generally unaffected by salts/chlorides, making it the most reliable choice for salty wastewater.

4. Summary of Trade-offs

| Feature | Optical Sensor (UV-Vis) | COD Analyzer (Wet Chem) | TOC Analyzer (Combustion) |

|---|---|---|---|

| Initial Cost | Moderate ($10k – $20k) | Moderate ($15k – $25k) | High ($25k – $40k+) |

| OpEx (Yearly) | Low (Cleaning, seals) | High (Reagents, waste disposal) | Medium (Gas, catalyst, reagents) |

| Maintenance | Weekly cleaning (simple) | Monthly reagent refill (complex) | Monthly maintenance (complex) |

| Accuracy | Good for trends (+/- 10-20%) | High (+/- 5%) | Very High (+/- 2%) |

| Waste | None | Toxic Chemical Waste | Minimal/Non-toxic |

Final Recommendation

- For Municipal WWTPs: Use Optical Probes (UV-Vis) calibrated to COD or BOD. They are cheap to run and perfect for watching daily trends and controlling aeration. Continue traditional Lab BOD for legal compliance.

- For Industrial WWTPs: Invest in a TOC Analyzer if you have complex/toxic waste or strict spill-detection needs. If your waste is simple (food/beverage), an Optical Probe is likely sufficient and cheaper.